How Robotics Are Changing the Manufacturing Industry

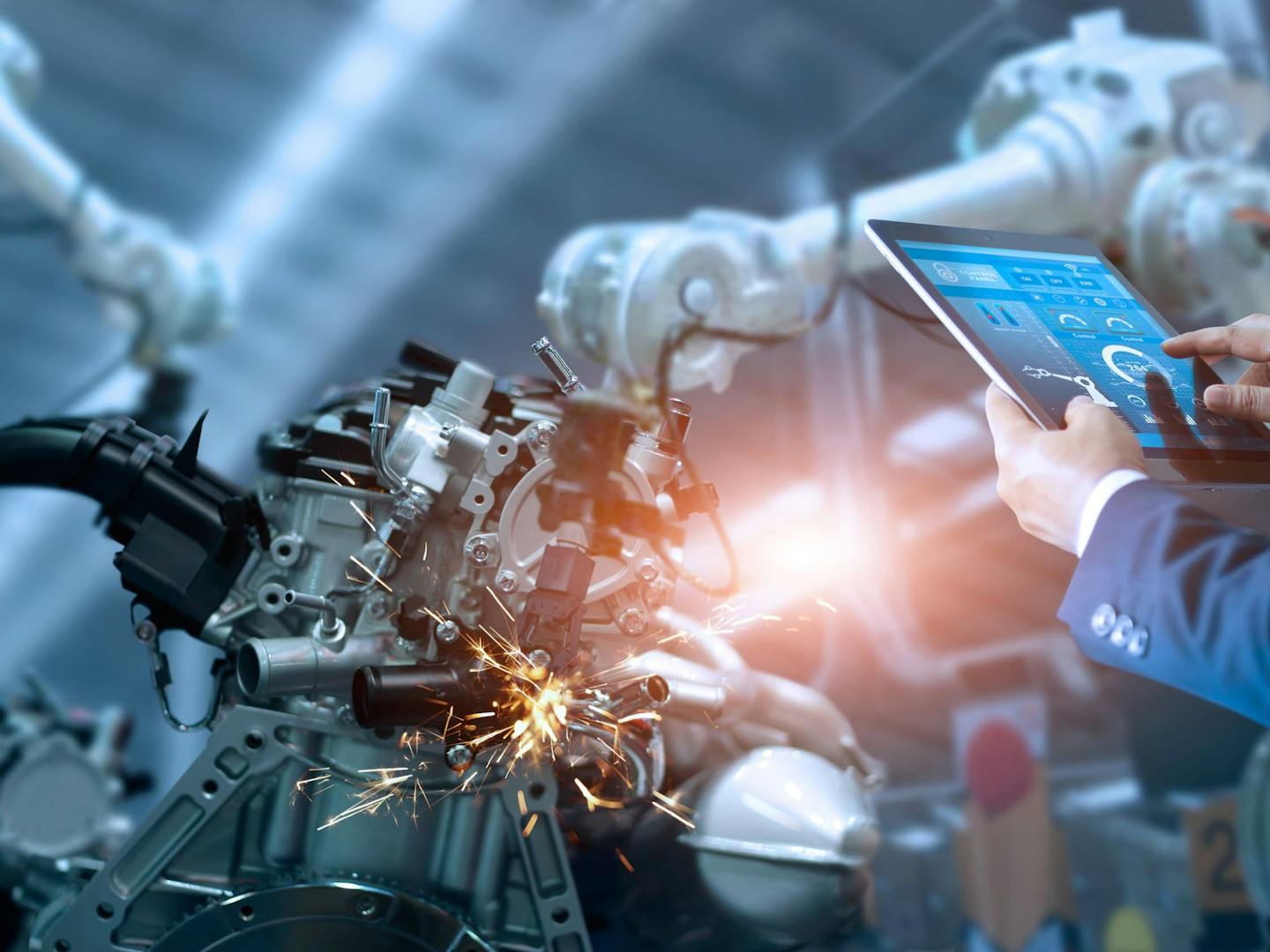

Robotics have already had a profound influence on manufacturing. Discover five ways that robotics and manufacturing software are revolutionizing the manufacturing industry.

In this article we cover

General Motors began implementing robotics on their assembly lines in 1962, and half a century later, almost nothing is the same. The manufacturing industry is well into the age of automated assembly, and perhaps the most amazing aspect is how quickly the technologies are still evolving every day.

Businesses around the world have implemented automation in their manufacturing processes, and industry leaders are finding new and creative ways to push these incredible technologies forward. Here are five trends in robotics that are challenging old models and driving the manufacturing industry into the future, plus a few insights on how manufacturing ERP software is helping the process along.

One of the manufacturing world’s biggest challenges in embracing automated manufacturing? The many legacy software systems that simply aren’t equipped to handle the challenges of running a fully- or partially-automated factory floor.

In order to remain competitive, many manufacturers will soon need to find a manufacturing software solution that allows integration with automated manufacturing processes. Some of the top manufacturing ERP software systems now build these capabilities into their software to allow businesses to expand their capacities in this critical area. The centralized platform model of ERP software is often a great match for robotics professionals who need access to a great deal of data at their fingertips to create efficient automated workflows.

3. Collaborative Robotics

On the other end of the spectrum from the lights out model is another approach that’s become increasingly popular: collaborative robotics. Rather than replacing human labor, collaborative robotics manufacturing combines the power of humans and robots to produce high-performance manufacturing.

Collaborative robots come in many shapes and functions, from robots that use human guidance to learn their tasks to robots that work fully independently but use safety guide features to protect their human counterparts. The common theme is that they’re moving toward a workplace in which the flexibility and ingenuity of a human mind can work side by side with the efficiency and consistency of a robot.

4. China Bets on Robots

China’s ascent to manufacturing dominance was one of the major stories of the late 20th century. As the Chinese manufacturing sector seeks ways to continue its growth, they’re increasingly betting on robotics as the new standard. The Chinese electronics, electrical and auto manufacturing industries have all made historically large investments in robotics in the past several years, and that trend seems on pace to continue as the country tries to position itself as the leader in manufacturing. The conventional wisdom of the past two decades has been to look to China to see where manufacturing is going and, right now, that arrow points decisively at an increasingly automated factory.

Robotics Meets the Sharing Economy

When automated manufacturing first became widespread, there was well-founded concern that smaller businesses wouldn’t be able to compete because of difficulty in making the large capital investments required to automate. Now, it seems that the sharing economy may have found a solution for this problem as well: robotics as a service.

Increasingly, smaller manufacturers are able to access automated manufacturing solutions thanks to programs not unlike the software as a service revolution of the past decade. Robotics manufacturers have created services to rent robots by the hour, unit or acre, and small businesses in agriculture and manufacturing alike are taking advantage of these new business models to catch up to their larger competition. The unified data platform of an ERP system can provide significant assistance here as well, as it’s important for a company using contract robotics to have robust automation procedures that are ready to plug-and-play with any robotics system.

As robotics technology continues to mature, it’s no exaggeration to say that it could produce something of a “second industrial revolution” for 21st century manufacturing. The technologies are no longer advancing merely in a linear path of efficiency improvements but also in radial paths of increasing utility across numerous different industries. As the industry’s leaders forge exciting new paths in robotics, manufacturing and distribution software is there to help these technologies find their footing and grow into productive solutions.

Robotics have already had a profound influence on manufacturing, and that trend will only get more pronounced. Discover five ways that robotics and manufacturing software are revolutionizing the manufacturing industry every day.

Congratulations, you're a step closer to finding the right ERP System.

A confirmation email from Top10ERP.org is on its way to your inbox. This email will include information on the resources you requested.

Thank you for visiting Top10erp.org. We greatly value hearing from our visitors. Please share your comments, questions and feedback regarding your experience on Top10ERP.org.